Premium Dredging Equipment – Engineered for Efficiency & Durability | Bama Dredge

Explore Our Cutting-Edge Dredging Machinery

Explore Our High-Performance Dredging Fleet

At Bama Dredge, we operate a highly specialized fleet of dredging equipment built for precision, durability, and efficiency. Our core systems feature heavy-duty slurry pumps and dredges from EDDY Pump, engineered to handle abrasive, high-solid materials with minimal wear. We also utilize Hawk Excavator attachments for targeted sediment removal and DAE Pumps for high-performance dewatering and water management.

This combination allows us to tackle a wide range of dredging challenges—from channel deepening and shoreline restoration to pond desilting and industrial sediment removal. Every piece of dredging equipment in Alabama we deploy is selected for optimal performance, ensuring each project meets strict technical and environmental standards.

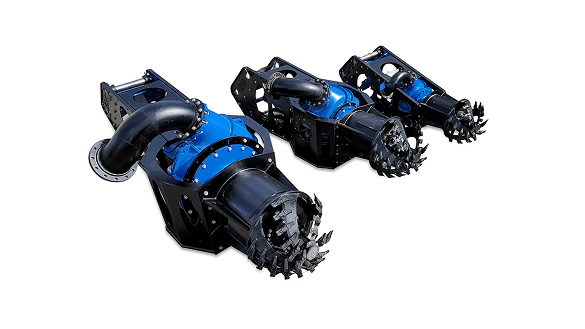

Excavator Pump Attachments

For high-volume sediment removal and dewatering, our excavator pump attachments from EDDY Pump offer a direct upgrade to traditional methods. These high-efficiency excavator attachments convert standard machines into powerful hydraulic or electric slurry-handling units, ideal for aggressive pumping applications in sludge, slurry, and solids-laden water. Designed for minimal clogging and maximum throughput, these attachments for excavators bring operational flexibility and efficiency to dredging environments where precision and reliability are non-negotiable.

We offer both hydraulic excavators pump attachments and electric excavator pump attachments, allowing our clients to adapt to job-specific power requirements. Whether outfitting long-reach machines or amphibious carriers, these systems are engineered for durability under extreme conditions. As a leader in dredging equipment in Alabama, we deploy this technology across a variety of terrain types and project scopes—always aiming for productivity without compromise.

Excavator Pump Attachment Options

- Flow Rate: 700–4,000 GPM (up to 350 yd³ per hour)

- Extended Reach: Long-reach dredge boom for optimal coverage

- Deep Dredging Capability: Depths of up to 85 ft

- Multiple Sizes Available: 4″, 6″, 8″, 10″, and 12″ configurations

- Efficient Material Removal: Cutterhead for compact material dredging

- Enhanced Material Breakup: Optional water jetting ring for agitation

- Liner-Safe Operation: Designed for dredging clay, poly, or concrete liners

- Flexible Power Options:

- Hydraulic power from excavator

- Standalone hydraulic power unit (HPU)

- Electric drive system

- Versatile Head Configurations: Choose between cutterhead or non-clog designs

- Precision Dredging: RTK/GPS positioning for accurate operation

Product Features

- Non-Clogging Design: Engineered to prevent blockages and ensure smooth operation

- High Solids Handling: Capable of processing dense, solid-laden materials

- Handles High Viscosity & Specific Gravity: Efficiently manages thick, heavy slurries

- Abrasion-Resistant Construction: Built to withstand highly abrasive materials

- No Critical Tolerances: Robust design eliminates precision wear points

- Low Maintenance: Simplified for easy servicing and reduced upkeep

- Minimal Downtime: Reliable performance for continuous operation

- Cost-Effective Ownership: Lower operational and maintenance expenses over time

Dredge Sled Equipment

Built for still water environments, the Dredge Sled is a specialized, surface-skimming sediment removal tool engineered for low-impact, high-efficiency operations. Whether deployed as a pond dredging sled, lagoon dredging sled, or general-purpose sediment removal dredging sled, its low-profile design and robust suction capabilities allow it to tackle dense deposits while preserving water quality.

Its rugged build makes it a go-to option when reliability is critical and downtime is not an option. Our team uses this dredge sled equipment for clients who need consistent sediment removal without the need for large, floating dredges. As one of the most trusted dredging consultants in the region, we stand behind the Dredge Sled as a cost-effective and technically sound solution.

Applications of Our Dredge Sled:

- Environmental Dredging: Restore and maintain lakes, rivers, canals, ponds, and navigational waterways

- Mining Solutions: Manage tailings ponds, maintain process ponds, and recover valuable heavy metals

- Wastewater Treatment: Clean sedimentation ponds, settling basins, and digester tanks efficiently

- Energy Industry: Remove sediment from power plants, refineries, and fly ash containment areas

- Industrial Maintenance: Service chemical storage ponds and optimized dewatering systems

- Agricultural Use: Desilting irrigation canals, farm ponds, and water storage dams

Cable-Deployed Dredge Pumps

When access is restricted, or precision is critical, we turn to cable-deployed dredge pumps. These submersible units can be lowered from winches or cranes, offering accurate placement and deep reach into sediment-heavy zones. Ideal for pits, tanks, harbors, and confined areas, they come in both cable-deployed hydraulic dredge pumps and cable-deployed electric dredge pumps, depending on site logistics and energy availability.

These systems offer the power of full-scale dredging with a compact footprint, perfect for clients requiring mobility and control. With minimal mechanical wear and robust solids handling, cable-deployed systems are key components in our arsenal of high-performance dredging equipment in Alabama.

Typical Applications

- Barge Unloading: Efficient material transfer from barges to shore

- Deep Water Dredging: High-capacity sediment removal in deep aquatic environments

- Mining Support: Tailings management, pond maintenance, and mineral recovery

- Sand & Aggregate Production: Extraction and processing for construction materials

- Oil & Gas Industry: Sediment removal in refineries and containment areas

- Fly Ash & Coal Ash Handling: Safe and effective dredging of ash ponds

Deploy Via Cable with

- Crane

- A-Frame Barge

- Excavator

Diver-Operated Dredge Pumps

For environments that demand hands-on precision, our diver-operated dredge pumps enable direct sediment removal in complex or sensitive areas. These pumps are available in both diver-operated hydraulic dredge pumps and diver-operated electric dredge pumps, allowing flexible integration into underwater operations. Designed with rugged submersible construction, they provide divers with powerful suction while maintaining control over material flow.

These submersible diver-operated pumps are ideal for maintenance dredging, structural cleaning, and situations where remote or cable-deployed systems aren’t viable. Built for endurance and ease of deployment, they are vital for specialized applications where human oversight ensures optimal outcomes.

Pump Features

- Clog-Free Operation: Specially engineered to prevent jams and maintain continuous flow

- Heavy-Duty Solids Processing: Handles high-density materials with ease

- Thick Slurry Capability: Efficiently manages viscous fluids and high-specific-gravity mixtures

- Abrasion-Resistant Construction: Built to withstand harsh, gritty materials

- Forgiving Design: No precision wear points to maintain

- Easy Maintenance: Simplified design reduces service requirements

- Maximum Uptime: Reliable performance minimizes operational interruptions

- Cost-Efficient: Delivers lower total cost of ownership through reduced maintenance and downtime

Diver Dredge Overview

- Standard Sizes: Most commonly available in 4-inch and 6-inch configurations

- High-Density Pumping: Capable of handling slurries with 40–60% solids content

- Multiple Operator Capacity: The system supports 1–3 divers working simultaneously

- Extended Reach: Includes 300+ feet of suction hose for wide operational range

- Long-Distance Transfer: Effective pumping over distances exceeding 2,500 feet

- Flexible Power Solutions: Available in both electric and hydraulic configurations

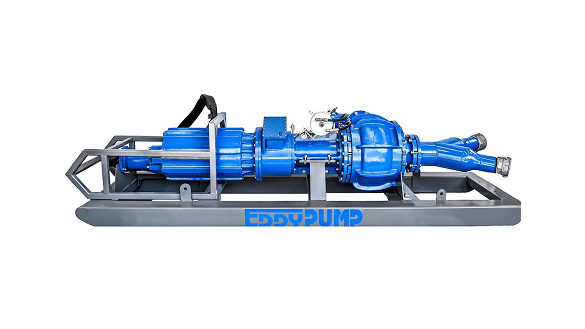

Self-Priming Slurry Pumps

Self-priming technology plays a key role in remote and demanding dredging applications. Our fleet includes self-priming slurry pumps designed for high-solids transport and continuous-duty pumping. These units eliminate the need for manual priming, drastically reducing downtime and simplifying startup procedures.

Available in self-priming electric dredge pumps and self-priming diesel-driven dredge pumps, they offer scalable solutions for a wide range of flow rates and head requirements. Whether used for sediment transfer, tailings, or emergency pumping, our self-priming dredge pumps are engineered for rugged field performance and long-term reliability.

Advantages of Self-Priming Pumps from EDDY Pump

- Self-Priming EDDY Pump System: Combines our proven pumping technology with automatic priming for instant startup and continuous operation.

- Integrated Vacuum Assist: The secondary pump system guarantees reliable priming in all operating conditions.

- Industrial-Grade Performance: It delivers wet-vacuum power at scale for demanding applications.

- High-Density Material Handling: Processes challenging slurries containing 30–70% solids without hesitation.

- Dual-Power Versatility: Choose between electric or diesel power to match your job site requirements.

- Ultra-Reliable Non-Clog Design: Specifically engineered to pump viscous, abrasive, dense, and corrosive materials that defeat standard pumps.

- Debris-Processing Confidence: Handles problematic materials like rags, rocks, and stringy waste that typically cause pump failures.

- Flexible Installation Options: Configure as skid-mounted, trailer-based, or stationary systems to fit your operational needs.

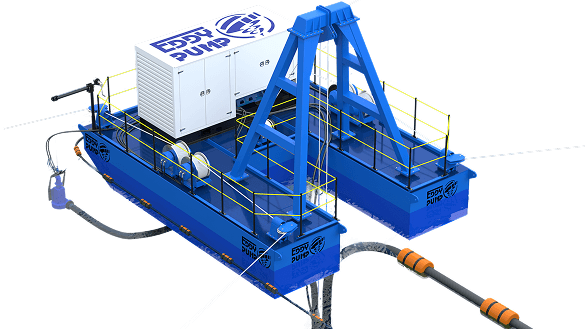

Remote Operated Dredges

When operator safety and operational distance are key concerns, our remote-operated dredges provide the ideal solution. These remote-control dredging equipment systems allow real-time control from shore or barge platforms, reducing exposure to hazardous environments. Ideal for industrial lagoons, wastewater facilities, and environmentally sensitive areas, these remote dredging solutions balance power with precision.

With minimal crew requirements and advanced control systems, including optional automation and telemetry, these units maximize productivity and safety. Remote dredging isn’t just a luxury—it’s quickly becoming an operational standard for projects requiring efficiency and oversight in equal measure.

EDDY Pump Advantages

- Smart Operation: Remote-controlled and autonomous capabilities enable precise, efficient dredging operations

- Clog-Free Performance: Patented pump technology handles viscous, abrasive, and corrosive materials with zero clogging

- High-Density Slurry Expertise: Industry-leading 40–70% solids handling capacity for maximum productivity

- Large Debris Capability: Processes objects up to 12″ in diameter without system disruption

- American Engineered Quality: 100% designed and manufactured in the USA for unmatched reliability

- Innovation Backed by R&D: Supported by cutting-edge research facilities driving continuous technological advancement

- Tough Debris Handling: Easily manages rags, rocks, and stringy materials that stop conventional systems

Pump Features

- Clog-Proof Technology: Engineered to eliminate blockages from rags, debris, and solids

- Extreme Solids Handling: Processes slurries with up to 70% solids content

- Viscous Fluid Expertise: Handles thick, high-specific gravity materials with ease

- Abrasion-Resistant Construction: Built to withstand sand, gravel, and harsh particulates

- Forgiving Operation: No precision clearances to maintain or recalibrate

- Maintenance Simplified: Reduced service requirements and easy access points

- Maximum Uptime: Robust design ensures continuous operation when you need it most

- Cost-Smart Solution: Lower lifetime costs through durability and efficiency

Earth Moving Equipment

Our dredging operations are reinforced with a modern fleet of earth-moving equipment outfitted for site prep, spoil handling, and access road development. We use machines integrated with long-reach excavator kits, amphibious undercarriages, and RTK GPS positioning systems to enhance precision during excavation and spoil placement.

These systems are essential in soft ground or fluctuating water levels, where stability and reach dictate project success. Our excavators are frequently paired with excavator pump attachments or dredge sled equipment, depending on the site conditions and sediment characteristics.

Long Reach Arm Kit Includes

- Boom Assembly: 1 unit

- Stick Assembly: 1 unit

- Premium Hydraulic Bucket Cylinder: 1 unit

- Hydraulic Tubing with Clamping System: 1 set

- High-Pressure Hydraulic Hose Assembly: 1 set

- Bucket Linkage with Mounting Pins: 1 set (2 pins included)

- Bucket Pivot Pins: 2 pieces

- Arm Cylinder Pin: 1 piece

- Yoke Pivot Pin: 1 piece

- EM-Compliant Bushings: Full set

- CE-Certified Bucket with Teeth: 1 unit

- Hydraulic Bucket Cylinder Seal Kit: 1 set

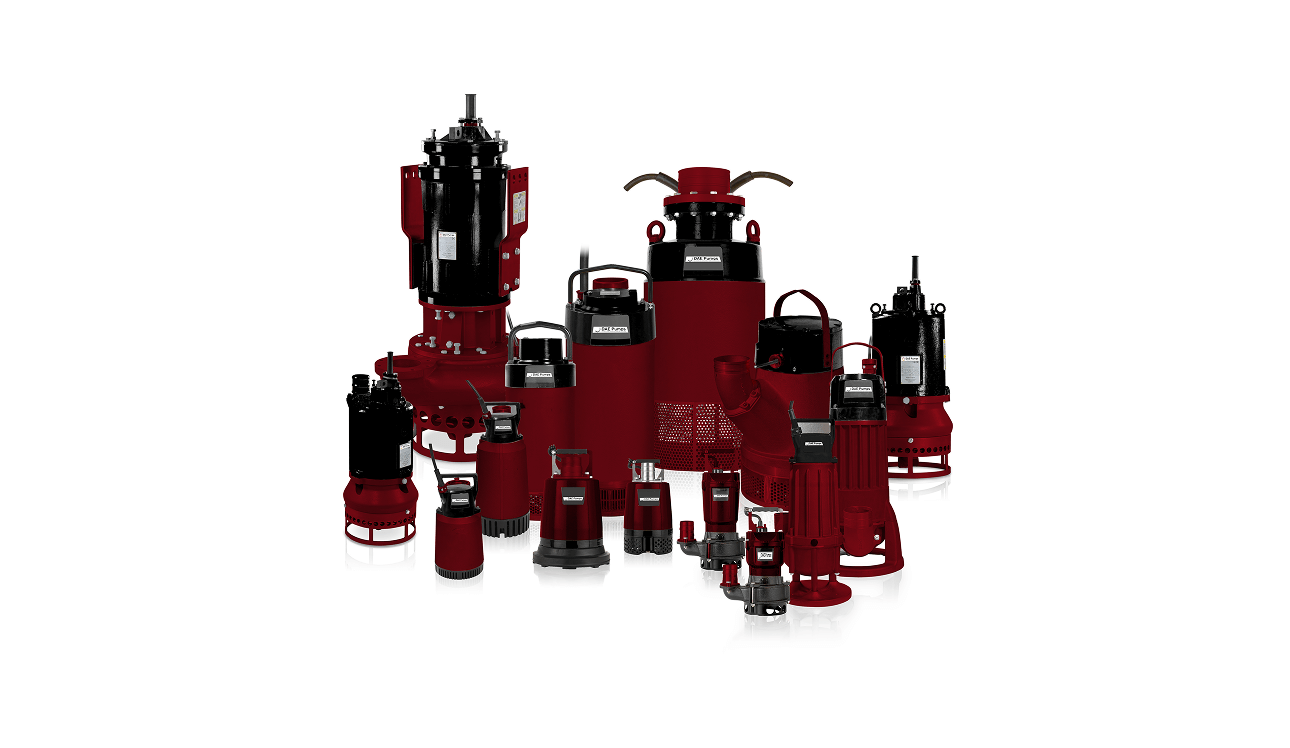

Dewatering Equipment

Efficient water management is critical to dredging success, and our dewatering equipment is designed to perform under the most challenging site conditions. From submersible dewatering pumps for flooded trenches to self-priming dewatering pumps for larger drainage zones, we offer adaptable systems engineered for non-stop, debris-tolerant operation.

Whether you’re managing groundwater infiltration or post-dredge sediment drying, these pumps ensure reliable performance and minimal maintenance. Integrated into our dredging workflows, these dewatering pumps deliver critical support that keeps projects moving on schedule and under budget.

bama dredge

frequently asked questions

What dredging services does Bama Dredge offer, and what advanced equipment is used?

Bama Dredge provides comprehensive dredging solutions, including environmental remediation, marine construction, and sediment removal. We utilize state-of-the-art remote-operated dredges, dredge sleds, and high-efficiency slurry pumps to ensure precision and productivity in every project.

Does Bama Dredge use advanced marine dredging technology?

Yes. Our operations incorporate cable-deployed dredge pumps and self-priming slurry pumps, allowing for efficient sediment removal even in challenging underwater conditions. These systems minimize downtime and maximize material recovery.

What projects are suitable for your excavator attachments and long-reach dredging equipment?

Our excavator-mounted dredge kits and long-reach boom systems are ideal for inland waterway maintenance, pond/lake restoration, and industrial cleanup. These attachments provide flexibility for both shallow and deep dredging applications.

What makes Bama Dredge’s solutions unique?

We integrate RTK GPS positioning, remote-control dredging systems, and non-clog pump technology to deliver unmatched accuracy, efficiency, and reliability—even in abrasive or high-solids environments.

Are self-priming slurry pumps available for tough dredging jobs?

Absolutely. Our self-priming slurry pumps excel in harsh conditions, handling viscous sediments, debris, and abrasive materials without clogging, ensuring continuous operation with minimal maintenance.

Why choose remotely operated dredges for precision work?

Remote-operated dredges provide real-time control, deep-water access, and minimal turbidity, making them ideal for sensitive ecosystems, industrial sites, and precision dredging in both shallow and deep water.

How do cable-deployed dredge pumps improve sediment removal?

Cable-deployed systems allow deep-water reach, flexible positioning, and high solids handling, significantly boosting efficiency in large-scale sediment removal projects.

Can Bama Dredge supply diver-operated dredge pumps?

Yes. Our diver-operated dredge pumps are designed for specialized underwater tasks, offering direct control in confined or complex dredging environments.

Do you offer dredge sleds for shallow or sensitive areas?

Yes. Dredge sleds provide low-impact sediment removal in shallow waters, wetlands, and environmentally sensitive zones, reducing disturbance while maintaining high productivity.

How do your dewatering pumps support large-scale operations?

Our submersible and high-capacity dewatering pumps ensure efficient water removal during dredging, earth-moving, and sediment processing, keeping projects on schedule and within budget.