Three Decades of Efficient Material Separation & Water Treatment Solutions

Advanced Technologies for Cleaner Operations and Sustainable Results

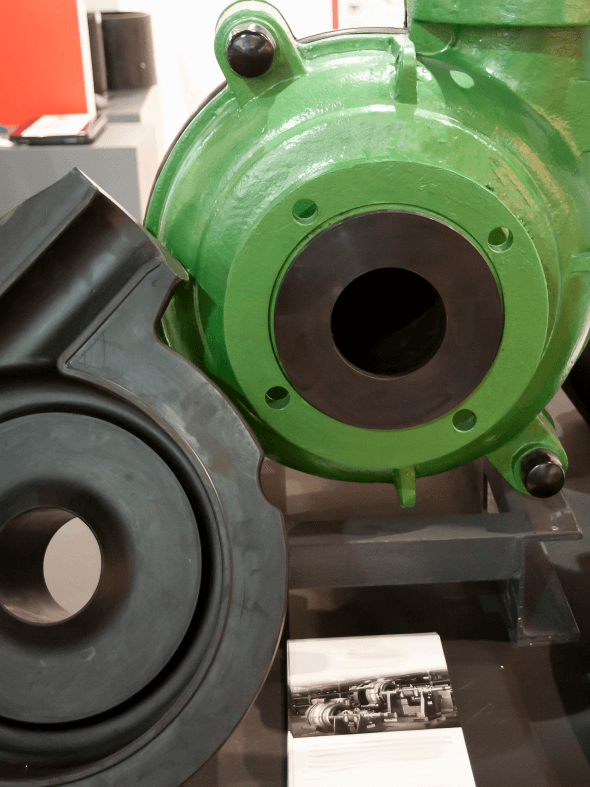

Manufacturers of High-Performance Separation Equipment

At Bama Dredge, we specialize in delivering advanced material separation solutions engineered to meet the rigorous demands of the dredging industry. As one of the most reliable Separation Equipment Manufacturers in Alabama, our focus is on integrating high-efficiency sedimentation processes and industrial-grade separation systems to improve throughput, accuracy, and overall performance in the field. From abrasive sediment layers to mixed composite slurries, our equipment is designed to handle a wide range of materials while maintaining optimal processing efficiency. With deep technical expertise and a commitment to precision, our systems help streamline operations and reduce downtime across diverse dredging environments.

As trusted Separation Equipment Manufacturers, our technologies go beyond conventional separation methods by incorporating innovative material-handling systems that enhance post-separation transport and disposal. Whether the project calls for onshore dewatering, barge loading, or environmentally compliant waste routing, our solutions support every stage of the dredged material lifecycle. Our sedimentation process ensures cleaner separation results, while our engineered transport frameworks facilitate the smooth movement of extracted materials. Bama Dredge is the go-to resource for specialized separation equipment built to deliver maximum efficiency and long-term value in dredging operations.

Equipment for Material Separation & Water Treatment

Advanced Vacuum Dewatering Solutions for Slurry Management

Bama Dredge offers one of the most efficient and technologically advanced vacuum dewatering systems in the market today—purpose-built for high-performance slurry separation and sediment handling. Engineered with field-proven vacuum sediment dewatering capabilities, this system drastically reduces drying times and increases overall operational throughput across complex dredging environments.

Our integrated system utilizes high-efficiency dewatering vacuum pumps designed for continuous-duty operation, ensuring reliable performance even under heavy slurry load conditions. These pumps facilitate rapid slurry vacuum dewatering, enabling faster dewatering cycles and reduced project turnaround time. Whether deployed in riverbed remediation or industrial basin cleanouts, our system ensures productivity without compromising precision.

The modular architecture of our vacuum dewatering equipment allows seamless integration into a wide range of dredging platforms. This adaptability supports various flow capacities and sediment compositions, making it a valuable asset for operations requiring scalable slurry management solutions. Each unit can be configured based on site-specific flow rate, solids concentration, and discharge requirements.

Our vacuum-based separation technology is engineered to handle abrasive and high-solids-content slurries with minimal clogging and maintenance. The robust system ensures uninterrupted processing, delivering consistent performance across diverse sediment profiles. This superior vacuum sediment dewatering capability results in cleaner filtrate and easier solid disposal.

Built to exceed environmental standards, the system employs refined slurry separation techniques that improve effluent quality and reduce total suspended solids (TSS) in the discharge stream. Cleaner separation not only enhances compliance but also minimizes downstream processing costs—an essential benefit for environmentally sensitive dredging zones.

As part of a full-service dredging and consulting offering, we provide tailored solutions that include equipment integration, process optimization, and post-dewatering material handling strategies. Our advanced slurry vacuum dewatering technology is engineered to deliver maximum value across every stage of the project lifecycle.

When precision, reliability, and speed matter most, Bama Dredge delivers vacuum dewatering systems that redefine operational efficiency in slurry handling.

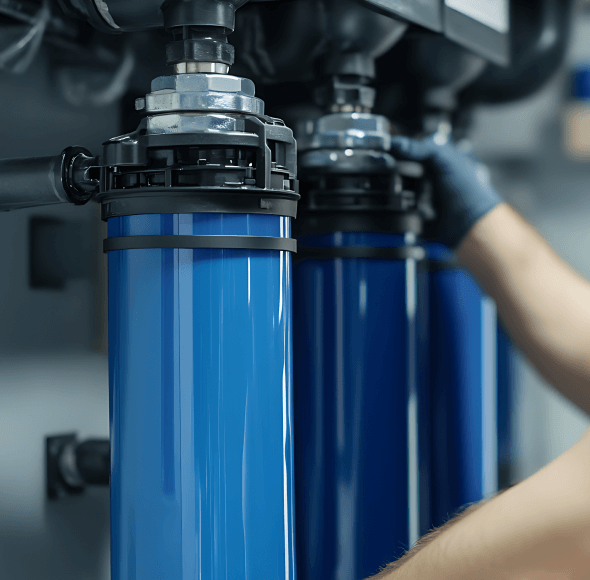

High-Performance Geotextile Tubes for Advanced Dewatering Applications

As a leading dredging solutions provider, Bama Dredge delivers precision-engineered geotextile tubes designed for high-efficiency slurry dewatering and sediment containment. Our systems support a wide range of dredging and environmental remediation projects, utilizing innovative geotextile tube dewatering technology to enhance solid-liquid separation while maintaining regulatory compliance.

Our high-capacity dewatering geotextile tubes are built to manage substantial volumes of slurry with minimal operational interruption. Engineered for strength and permeability, these tubes allow for continuous sediment loading while effectively separating solids from water. This is especially critical for projects that involve sustained dredge cycles or the removal of high volumes of suspended solids.

Geotextile tube systems are among the most economical approaches to dewatering available today. By eliminating the need for centrifuges or belt presses, our geotextile tube dewatering technology reduces capital and operational expenditures. These systems require less workforce, are easy to mobilize, and significantly cut disposal costs, making them ideal for projects with strict budgetary constraints.

Each sediment dewatering tube is fabricated to meet stringent environmental guidelines. As the slurry is pumped into the tube, water filters through the geotextile fabric, leaving behind a dense, consolidated solid that’s easier to handle and dispose of. The filtered effluent is often clean enough for direct discharge or reuse, aligning with best practices in sustainable dredging.

Our tubes utilize advanced filtration media tailored to specific particle sizes and flow rates, allowing for superior capture of fines and suspended solids. This ensures efficient solid-liquid separation, whether the slurry contains organic-rich sediments, industrial byproducts, or fine silt. The result is accelerated drying and a stable, stackable end product.

From municipal lagoons and water treatment plants to ports, harbors, and industrial sites, our geotextile tubes are suitable for a wide array of dewatering and containment needs. Their adaptability to different site conditions and sediment profiles makes them an invaluable tool in the execution of dredging and sediment management projects.

With these advanced capabilities, the geotextile tube systems offered by Bama Dredge represent a top-tier solution for efficient dewatering and reliable containment. Our expertise in sediment dewatering tubes and cutting-edge filtration technology ensures that your dredging operations are executed with maximum efficiency, cost control, and environmental compliance.

Engineered Pond Building Solutions for Dewatering and Sediment Control

As part of our integrated dredging and sediment management services, Bama Dredge offers expertly designed pond-building dredging solutions tailored for temporary dewatering operations. These engineered containment systems serve as critical infrastructure for managing slurry, controlling sediment dispersion, and supporting environmentally compliant discharge during active dredging.

Every site presents unique variables—soil composition, hydrology, and space constraints—and our team develops customized dredging for ponds to match those conditions precisely. Whether your project involves clay-heavy slurry or high fine content, we design temporary ponds with optimal capacity, geometry, and flow paths to maximize dewatering performance and sediment settling efficiency.

Our pond excavation and dredging process ensures that each containment pond facilitates proper hydraulic retention time and encourages passive sedimentation. This allows suspended solids to settle out effectively, while clarified water can be either recirculated or safely discharged. These systems are particularly effective in maintaining environmental compliance, especially in sensitive ecosystems where turbidity control is essential.

We deploy temporary pond systems with minimal lead time, supporting fast-paced dredging schedules without sacrificing operational control. This rapid response capability allows us to integrate sediment ponds directly into your dewatering workflow, reducing system lag and maximizing project continuity. Our experienced field crews specialize in fast-tracked earthwork execution and secure liner installations when required.

Whether supporting pond restoration dredging for small agricultural basins or large-scale industrial cleanup operations, our temporary ponds are engineered to adapt. The modular and scalable nature of our pond systems makes them compatible with a wide range of custom dredge equipment for ponds, enhancing operational versatility across diverse site conditions.

Building temporary containment ponds is a strategic and budget-conscious alternative to installing permanent infrastructure. Our solutions are dismantlable, relocatable, and optimized for short-to-medium-term operations—ideal for clients who need effective pond dredging services without incurring permanent land modification costs.

By combining technical precision with site-specific adaptability, Bama Dredge’s pond building and pond dredging services offer a dependable and environmentally conscious approach to dewatering. Our proven methods ensure effective sediment control, project efficiency, and regulatory compliance—delivered with the professionalism of one of the most trusted names in dredging consultation and execution.

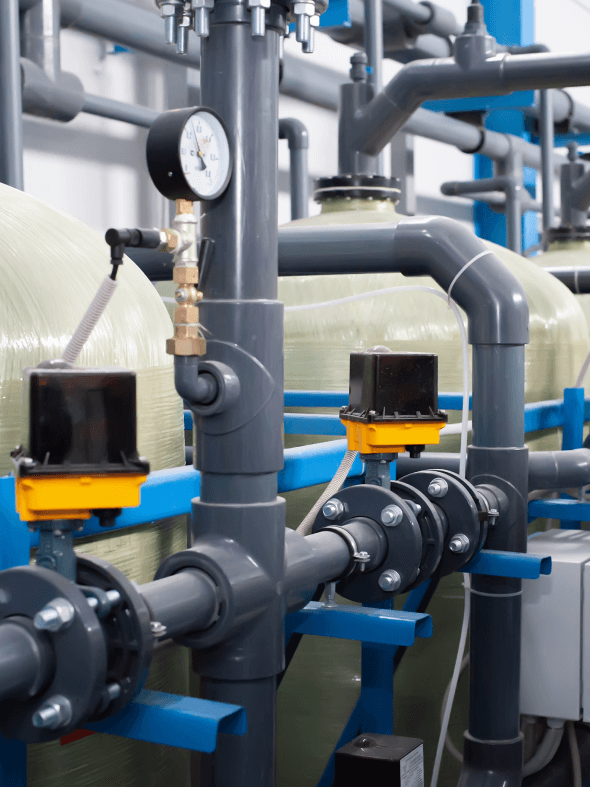

Comprehensive Water Treatment Solutions for Dredging Operations

At Bama Dredge, we specialize in delivering advanced, multi-stage industrial water treatment services tailored to meet the complex demands of dredging and environmental remediation projects. Our systems are engineered to treat, clarify, and disinfect process water with high precision—ensuring that every discharge meets or exceeds environmental compliance standards. These reliable water treatment solutions are designed for both onsite discharge and reuse applications, supporting project sustainability from start to finish.

Step 1: Pre-Treatment and Initial Screening

The water recovered during dredging activities is routed through mechanical screens and filtration barriers that efficiently remove large solids and debris. This initial phase of eco-friendly water treatment methods is critical in protecting downstream components and prolonging the life of treatment infrastructure.

Step 2: Coagulation and Flocculation

We apply targeted chemical dosing to destabilize colloidal particles, forming larger flocs through controlled agitation. These flocs accelerate sedimentation and are key to maximizing removal efficiency in high-turbidity environments typical of dredging projects.

Step 3: Sedimentation and Sludge Management

In dedicated sedimentation basins or tanks, gravity facilitates the separation of settled solids from clarified water. The resulting sludge is safely collected and managed according to regulatory protocols, ensuring minimal environmental impact.

Step 4: Precision Filtration

Following sedimentation, water is polished using high-performance filtration media such as multi-layer sand beds, anthracite, or membrane-based systems. These filtration technologies provide a critical barrier against fine particulates and residual turbidity.

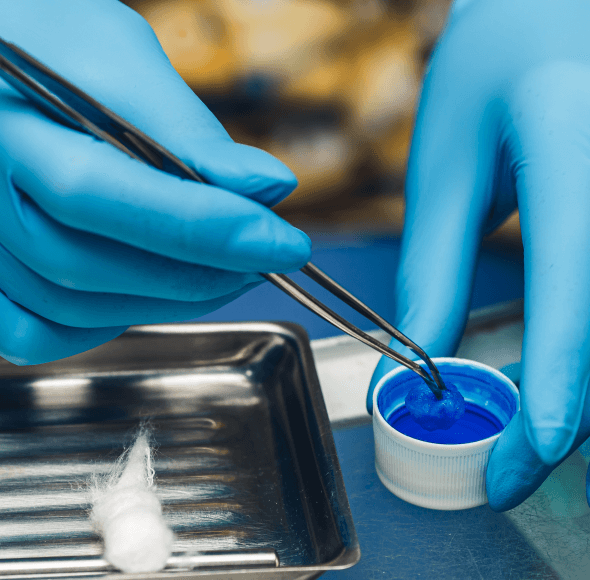

Step 5: Advanced Oxidation Processes (AOPs)

To degrade dissolved organics and neutralize harmful microbes, we employ advanced oxidation technologies such as UV disinfection, ozone injection, or hydrogen peroxide treatments. These methods enhance the overall disinfection capability without introducing harmful byproducts.

Step 6: Activated Carbon Adsorption

Using high-porosity activated carbon media, we eliminate trace organics, color, odor, and chemical residues that may compromise effluent quality. This adsorption phase is essential for projects demanding high-purity water outcomes.

Step 7: Final Disinfection

A final disinfection step ensures biological contaminants are completely neutralized. Depending on site conditions, this may involve UV irradiation or precise chlorination—offering flexible options for achieving safe water ready for reuse or compliant discharge.

Step 8: Monitoring, Compliance & Quality Assurance

We implement real-time water quality monitoring tools, ensuring that parameters such as TSS, pH, and COD remain within regulatory thresholds. Regular sampling and lab-based analysis support our rigorous quality control program, guaranteeing adherence to wastewater treatment services and environmental mandates.

By integrating these advanced treatment processes, Bama Dredge offers some of the most expert water treatment services available in the region. Our holistic approach to commercial water treatment solutions not only maximizes operational efficiency but also ensures environmentally sound outcomes. Whether your project requires large-scale water treatment services in Alabama or specialized point-of-use treatment, we provide scalable, compliant, and future-ready solutions.

Bama Dredge knows clean water matters – for communities, businesses, and our environment. We don’t just dredge – we provide complete water treatment solutions to ensure every project delivers water that meets strict quality requirements.

The Bama Dredge Treatment Method

As part of our specialized industrial water treatment services, Bama Dredge integrates advanced chemical and mechanical processes to ensure consistent water quality across dredging, remediation, and infrastructure support projects. Each stage of treatment is optimized for regulatory compliance, operational efficiency, and long-term system reliability—making us a trusted provider of commercial water treatment solutions in diverse sectors.

To deliver clean, compliant water every time, our treatment process follows these essential steps:

Coagulation and Flocculation

Process:

Targeted chemical dosing introduces positively charged coagulants to destabilize suspended solids and fine particulates. Through controlled mixing, these destabilized particles aggregate into larger, more easily removable flocs.

Outcome:

Enhanced particulate removal through improved sedimentation and filtration performance, forming the foundation of effective water clarification.

Sedimentation

Process:

Floc-laden water is directed into sedimentation basins, where gravitational forces allow solid particles to settle naturally at the tank’s base.

Outcome:

Efficient separation of clarified water from settled sludge, reducing turbidity and preparing the water for downstream treatment.

Filtration

Process:

Post-sedimentation, water flows through multi-layer filtration systems—such as sand, anthracite, or membrane media—to capture remaining suspended solids.

Outcome:

High-level removal of fine particulates, delivering clear, low-turbidity water suitable for disinfection or reuse.

Disinfection

Process:

Application of advanced disinfection techniques including chlorination, UV irradiation, or ozone treatment to inactivate pathogens and microbial contaminants.

Outcome:

Elimination of bacteria, viruses, and protozoa, ensuring microbiologically safe water ready for discharge or repurposing.

pH Stabilization

Process:

Precise chemical adjustment of pH levels to neutralize acidity or alkalinity, protecting downstream infrastructure and enhancing treatment efficiency.

Outcome:

Stable, corrosion-resistant water chemistry suitable for pipeline transport, reuse, or safe discharge into the environment.

Optional Fluoridation (Client-Specific)

Process:

In select applications, controlled fluoride dosing may be introduced to support dental health initiatives in municipal or public-facing water programs.

Outcome:

An optional value-added feature that contributes to long-term public health by reducing the prevalence of dental decay.

Final Conditioning and Distribution

Process:

Treated water is routed to secure holding reservoirs for final polishing and undergoes continuous online monitoring for quality assurance.

Outcome:

Reliable distribution of consistently high-quality water across industrial, commercial, or environmental endpoints—backed by rigorous safety standards.

bama dredge

frequently asked questions

What services do you offer for material separation and water treatment in Alabama?

Bama Dredge provides comprehensive material separation and water treatment solutions designed for efficiency, environmental compliance, and performance in challenging dredging environments. Our services include sediment separation, dewatering, sludge management, and custom system design using advanced material separation and water treatment equipment tailored to specific site conditions.

How does geotextile tube technology work for dewatering?

Our geotextile tubes are engineered to capture and contain sediments while allowing filtered water to pass through. The slurry is pumped into these high-capacity tubes, where solids are retained, and water is gradually released through the permeable fabric. This passive dewatering method reduces the need for mechanical systems and is ideal for sites where mobility and cost-efficiency are key.

Why is sedimentation important in water treatment for dredging projects?

Sedimentation is a fundamental phase in material separation and water treatment. It allows suspended solids and aggregated particles to settle naturally in tanks or ponds, creating a sludge layer that can be processed or removed. Effective sedimentation reduces the burden on downstream filtration systems and ensures cleaner effluent output.

What types of projects can benefit from Bama Dredge's material separation solutions?

Our solutions are suitable for a wide range of applications, including industrial basin cleanouts, municipal lagoon maintenance, port dredging, environmental remediation, and stormwater runoff control. Any operation that deals with high-solid slurry or contaminated sediments can benefit from our integrated material separation and water treatment equipment.

How does your brand ensure environmental compliance in its water treatment processes?

We implement best-in-class practices for effluent monitoring, chemical dosing, and sludge management. Each treatment system is designed with regulatory thresholds in mind, and our equipment is calibrated to maintain parameters like turbidity, pH, and contaminant levels within approved discharge limits. Our use of eco-conscious dewatering methods like geotextile tubes also supports sustainable operations.

What are the benefits of partnering with you for industrial water treatment dredging?

We offer site-specific, scalable systems that reduce downtime, improve operational flow, and lower total lifecycle costs. Our specialized team ensures that each project receives tailored solutions—from mobile material separation and water treatment equipment to long-term sediment control planning—making us a strategic partner in industrial settings.

Can you handle large-scale dredging and water treatment projects?

Yes, we are equipped to manage high-volume dredging projects that require advanced dewatering and full-scale treatment systems. Our modular equipment and rapid-deployment teams allow us to scale operations quickly, ensuring timely execution even on complex or geographically dispersed job sites.

What equipment does Bama Dredge use for water treatment?

Our equipment portfolio includes geotextile tubes, sedimentation tanks, mechanical separators, filtration systems, chemical dosing units, and sludge handling tools. Each component is selected based on the specific needs of the site, ensuring an optimal balance between efficiency and environmental responsibility.

How do you manage the disposal of dredged materials?

Once dewatered, dredged solids are processed for disposal, reuse, or offsite transport. We follow all regulatory guidelines for sediment classification and disposal, and whenever possible, we assist clients in identifying reuse opportunities—such as landfill cover or soil amendment—to reduce waste.

What makes Bama Dredge's water treatment solutions stand out?

Our edge lies in combining field-proven equipment with engineering expertise. We don’tdon’t offer off-the-shelf systems—we design material separation and water treatment programs that are responsive to real-world site variables. Our consistent use of efficient dewatering practices and innovative tools like geotextile tubes ensures both compliance and cost efficiency.